Being in a printing agency, you might have encountered numerous advanced technologies, and one that shines the brightest is DTF printing. The buzz for DTF printing in the respected field is all over, and people are actually choosing DTF over traditional printing methods. Such hype may make you wonder what DTF printing is and why people are actually going crazy for it.

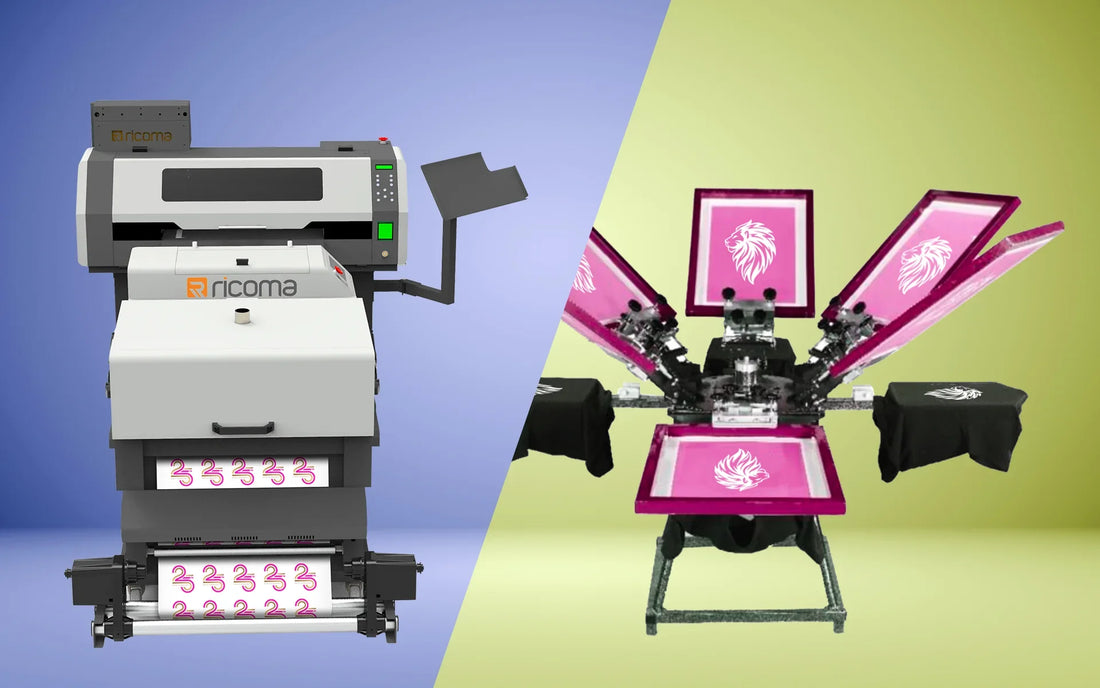

Well, there is so much to talk about. The more you dig into the details of DTF printing, the more you will uncover its magic. However, at this point, it is safe to say that DTF, or Direct-to-Film printing, has impacted the printing world with its ease and possibilities. Unlike old-schooled screen printing methods, DTF easily creates bright, durable designs on different fabrics, but again, you might wonder what exactly the difference is between them when they both do the same thing.

While screen printing might be outstanding for heavy orders and simple, striking designs, DTF gives it a new twist, as it prints fine details and even gradients. This aspect brings more possibilities for personalization, which is why DTF has become everyone's favourite.

DTF vs. Screen Printing: What's the Difference? In this article, we'll explore one of the key differences: comparing and contrasting screen printing with DTF in terms of process, cost, and other applications. We will keep you informed on which method best suits your needs.

Also see best DTF print in USA: Iltex Transfers

What is DTF Printing

DTF printing is the new kind that has changed the face of customization and garment printing. It basically prints designs on a special film that is transferred onto a wide range of materials and fabrics using a heat press. This technology brings together accuracy, durability, and flexibility, hence becoming a favourite for those who want to produce high-quality, vibrant designs efficiently.

DTF Printing Process

The digital artwork created on graphic design software is first sent to the DTF printer designed for printing on PET-polyethylene terephthalate film using four-colour carbon ink: magenta, cyan, yellow, and black and white. The white ink is a base layer to avoid darkness or colour washouts on dark or coloured fabrics.

The wet ink on the film is then coated with adhesive powder, known as DTF powder, which helps the design stick to the fabric properly in the transfer process. The powdered film is then heated to cure the adhesive and become ready for transfer.

A cured film is applied to the fabric using a heat press, and hence, the required temperature, pressure, and time settings are used so that the design sticks well. Once cooled, the film is peeled away, leaving behind a beautiful, durable print.

What is a Screen Printing?

A printing technique with a length and breadth of use, screen printing is also known as silk screening or serigraphy. Created from a stencil commonly referred to as a screen, it applies layers of ink onto a printing surface. This method is popularly used to print big, bold, and vibrant designs on fabrics, though it can also work on paper, glass, wood, and ceramics, among many others. It's widely used because it's versatile, long-lasting, and commonplace in garment production, advertising, and packaging.

Screen Printing Process

Screen printing starts by making a design, which is usually prepared digitally and separated into layers if the print requires more than one colour. A mesh screen is chosen and stretched taut over a frame, then coated with an emulsion sensitive to light. The design is transferred onto the screen by exposing it to UV light, which hardens the emulsion except where the design appears. Then, all the unhardened emulsion is washed away, and the stencil is ready to be printed.

Depending on the multi-coloured design, ink is pushed through the screen onto the material using a multiple-layer squeegee. Once printed, the material is cured with heat to set the ink, producing an intensive and stable output.

The Difference between DTF Printing and Screen Printing

The general difference is that DTF printing is ideal for intricate designs, small batches, and versatile materials, offering vibrant, detailed results with minimal setup. Screen printing excels in bulk orders and bold designs, delivering durable prints but requiring more time and preparation for multi-colour projects.

Printing Process and Technology

The main distinction between DTF and screen printing is in the process. DTF printing uses advanced digital machines to print designs on specialized PET films. After printing, the DTF has an adhesive powder applied over it, then dried by curing and heat-transferred onto the fabric. This process is relatively quick, precise, and ideal for detailed designs. Screen printing, in contrast, requires the creation of a stencil or screen for each colour in the print design. The ink is squeezed through these screens onto the fabric. Traditional in its approach, this method yields bold and vibrant prints but has an extensive setup, even for multi-colour designs.

Cost Efficiency and Order Sizes

When it comes to cost efficiency, DTF printing is the best of all. It has no setup-heavy process and instead can print just one with no additional costs incurred. It is ideal for a custom, unique design or project on a small scale. Screen printing, on the other hand, proves cost-effective only with a significant amount of items due to its substantial initial setup for screens.

However, screen printing’s efficiency in reproducing the same design multiple times makes it a preferred choice for bulk orders.

Design Versatility and Details

One of the biggest advantages of DTF printing is its ability to easily accept very intricate designs, gradients, and even photorealistic details. The digital nature of the process means there are virtually no limitations on complexity or colour variations.

Screen printing, on the other hand, although excellent for bold and excellent designs, fails at gradients and fine details. Each colour would require a separate screen, making multi-coloured or highly detailed designs more time-consuming and less precise than DTF.

Durability and Longevity

Both methods are known for producing durable prints, but they differ in specific aspects.DTF prints are less likely to crack or fade, as the adhesive and curing process ensures it will last long, even after multiple washes. Screen printing is also durable, with ink penetrating deep into the fabric, but the durability solely depends upon the ink and the wash conditions.

Both methods can deliver excellent results for applications where longevity under harsh conditions is critical, but DTF's resistance to wear makes it a strong contender.

Material Compatibility

DTF printing is highly versatile and capable of adhering to various materials, such as cotton, polyester, blends, leather, and even non-fabric surfaces. It allows any business to serve different customization needs. Screen printing is flexible but only used on flat, smooth materials, such as fabrics, paper, and sometimes paper. In contrast, other materials, such as leather or non-textile surfaces, may not be suitable for traditional screen printing techniques.

When to Choose DTF Printing

Such projects with photo-realistic quality designs, intricate patterns, gradients, or strong colours are ideal for DTF printing. Quick customization without extensive setup, making it perfect for small-batch orders, personalized products, or custom designs.

DTF can print on fabrics like cotton and polyester and hard surfaces like leather, among many other materials. This is particularly useful for companies targeting more diverse markets or those prone to being picky about design and materials.

When to Choose Screen Printing

Screen printing is ideally suited for a large order with bold and simple artwork. Though the setup process is time-intensive, it becomes cost-effective for bulk production, with a lower per-item cost as quantities increase. Known for its vibrant colours and durability, screen printing is a favourite for branding, promotional merchandise, and apparel requiring high-impact designs. However, relying on separate screens for each colour limits its efficiency for detailed graphics or one-off projects, making it the preferred choice for consistent, large-volume printing needs.

These differences can help you determine which printing method best suits the demands of your project, resulting in the best outcome for your money.

Conclusion!

DTF printing and screen printing are both different in their strength, so each one applies well to its various needs and application areas. DTF printing excels in flexibility, detailed imagination, and suitability for small-batch or custom orders.

Similarly, screen printing is an excellent option for high-volume orders and bold designs that do not fade fast. Its cost-effectiveness in bulk and gorgeous ink usage makes it popular for printing on promotional products and branding materials.

Ultimately, DTF vs. screen printing depends on the intricacy of your design, the size of your order, cost constraints, and material. Once you know the differences between these two methods, you can pick the one that will best serve your project so you get the right prints.